Reverse Mezzotint (Additive)

Additive technique on a mezzotint base.

Materials:

- Plate laminated with ImagOn

- Materials to explore include:

- Hunt Speedball Water Soluble Screen Filler 4570

- Molding (or modeling paste)

- gesso

- acrylic mediums

- pumice mediums

Overview:

- The Mezzotint Intaglio-Type represents a unique method of

working with the ImagOn film that displays working characteristics that

are similar ( but definitely not the same finished results) to traditional

mezzotint techniques.

One or more layers of ImagOn film are applied to the plate

-

Method One:

- all layers are exposed to the aquatint screen simultaneously

- ImagOn layers individually exposed between each lamination.

The developed ImagOn emulsion has a stippled surface similar to sandpaper and if the plate was inked and printed it should yield a rich black print.

To create an image from this black printing plate, you can manipulate the stippled ImagOn emulsion can be manipulated in three ways:

- sand into the ImagOn emulsion (subtractive Technique)

- "fill-in" the emulsion (Reverse Mezzotint-additive technique)

- combination of subtractive and additive techniques.

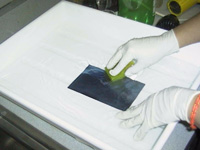

Once the ImagOn plate has been prepared in one of the above mentioned ways paint onto the surface of the stippled plate. These can be painted on to the plate in varying thicknesses and layers to fill-in the stippled surface of the ImagOn emulsion. The more the ImagOn emulsion is filled-in the lighter will those areas become. This is a very painterly technique. The thickest and smoothest areas of the filler will produce the lightest areas of the print. It is essential to wait for the plate additives to completely dry before attempting to print the plate.

Recommended procedure:

|

|

| . |

plate is developed and light-hardened. . To produce the desired image from this black printing plate you can use several ways to manipulate the developed ImagOn emulsion

|

|

Rubber gloves RECOMMENDED for the development procedure. Repeated use of developing solution can dry out the skin and cause a dermatitis reaction on the hands. Eye protection advised. The developer is an alkaline solution. Do not splash the developing solution into eyes.

|

Develop

|

Print

- see Printing Handout

Clean Up of Printing Plate and Inking Station

- Vegetable oil (canola) and a rag.

- Degrease with magnesium carbonate.

- Put up all paper, plates, inks on personal or appropriate studio shelf and drawers.

.

.

.

.