Laminate

(Apply) ImagOn to Plate Surface

ImagOn

has great adhesive qualities in addition to its photo sensitive qualities.

Materials:

|

|

Remove Mylar liner from

ImagOn film

- remove the top plastic peel back layer from the

film.

- The peel back layer is the inside surface of the

natural curl.

- To remove the inside plastic peel back layer

place the ImagOn film between the thumb and index finger and gently

push your thumb away from your index finger so that the texture of

your thumb print catches the edge of the peel back layer and causes it

to roll backwards. This technique takes time and practice to master.

- An alternative method:

- dog ear a corner of the ImagOn film and rub this

folded section against itself until the inside peel back layer

separates from the ImagOn emulsion.

Make sure that the inside peel back layer is removed

and not the outside Mylar layer. The inside plastic peel back layer has

a soft feel somewhat like Glad Wrap and the outside Mylar layer has a

stiffer feel similar to cellophane

|

|

|

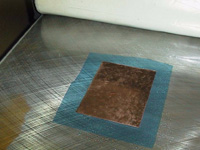

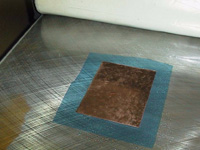

Place ImagOn on Press bed

with revealed "Sticky side up"

- placed onto a perfectly smooth surface

- This smooth laminating surface can be polished

stainless steel or Lexan.

If there is the slightest scratch or imperfection in

the laminating surface this will be imprinted in to the ImagOn film and

could be noticed in the finished print.

|

|

.

|

Handle the ImagOn film carefully as

mishandling causes dimples in the ImagOn film that can result in unwanted

marks in the finished print.

|

|

|

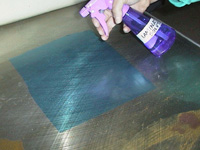

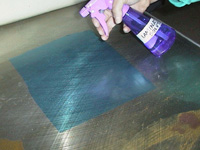

Spray Alcohol Laminating

Solution

- liberally spritzed with a plant mister containing

a lamination solution

- Laminating solution = required in dry climates

- Not needed in damp climates

|

|

|

- it is possible to adhere ImagOn with just water.

If water is used as the lamination solution it is advisable to allow

the plate to dry for several hours before using it.

- Some pre-etched or reworked surfaces may require

a stronger alcohol water mixture to cause the ImagOn to stick more

effectively. The more alcohol that is present in the spray the more

difficult it is to work with because the ImagOn will stick to the

plate too quickly.

|

|

|

Place prepared plate

prepared side down onto ImagOn Film

|

|

|

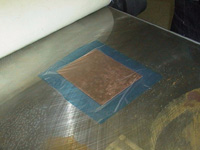

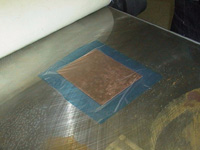

Replace mylar covering or

place newsprint over plate and film

- Replace mylar covering or newsprint over the

plate to protect the press blankets from the Imagon adhesive

|

|

|

Fuse the ImagOn to the Plate

- lower etching blankets over the entire plate

- run through the press in the same manner in which

a print is made from an inked plate.

- slowly.

- The speed of the press bed moving through the

press rollers, during lamination, should be roughly one foot every 12

seconds.

Normal etching blankets are used and the pressure of

the press is set slightly tighter than what would be required to print a

fine aquatint.

|

|

|

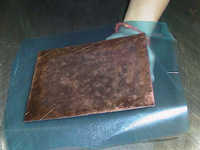

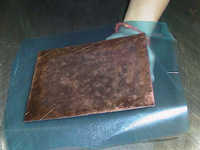

Trim edges of film around

plate

- final trimming to ensure that the ImagOn emulsion

is cut flush with the edge of the plate.

- trimming knife has a very sharp blade

- cut down on the ImagOn film in such a way that

the cutting action will not cause the edges of the ImagOn film to lift

away from the plate.

|

|

|

- ImagOn film trimmed from the plate these small

pieces of ImagOn can be recycled.

- See "Liquid ImagOn for Reworking the

Plate".

|